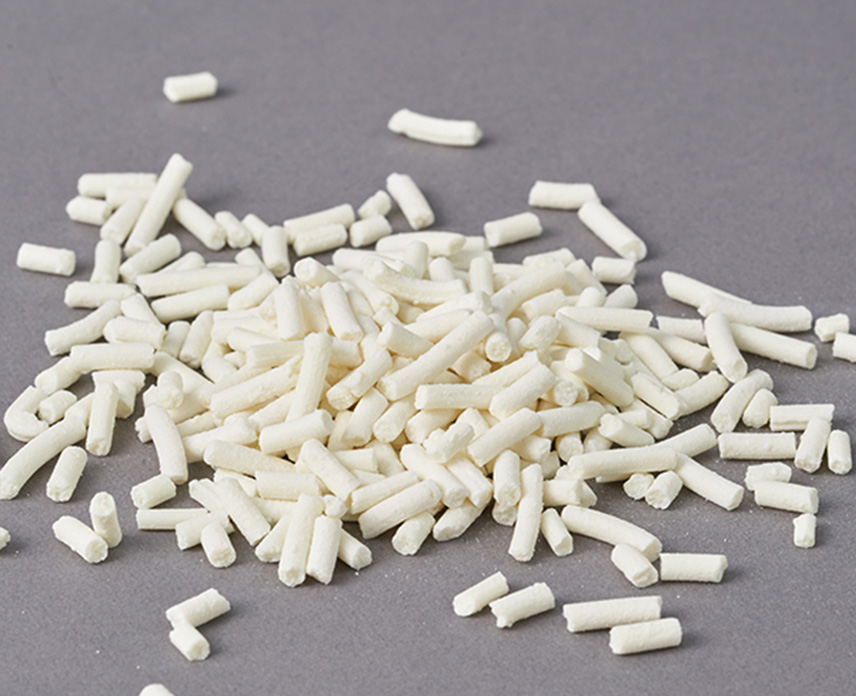

硬质PVC颗粒

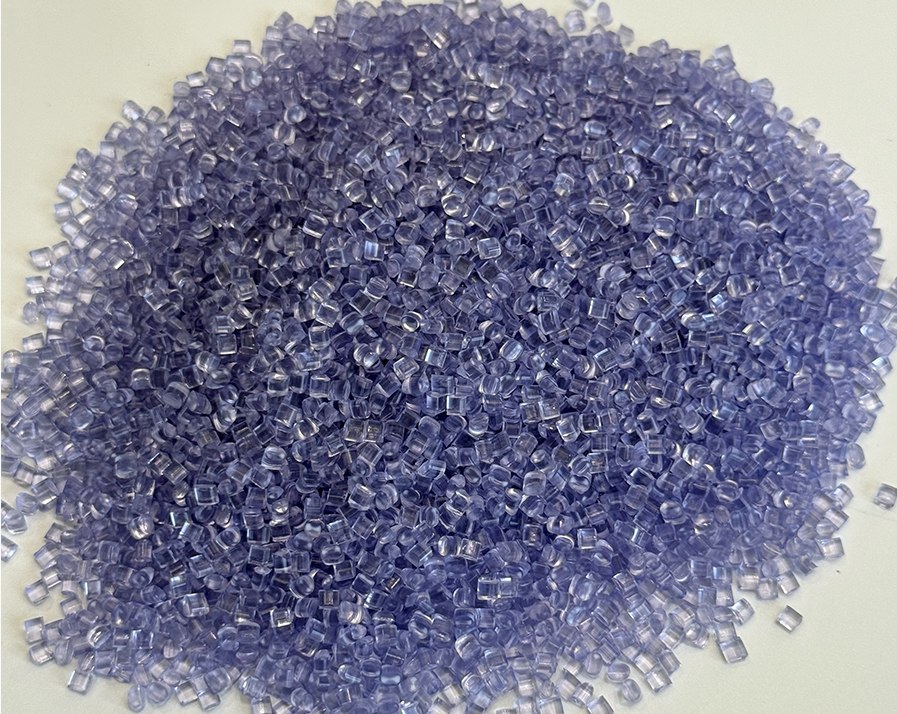

高透明硬质PVC颗粒

PVC硬质透明颗粒具有优异的物理性能和加工适应性,尤其以高抗冲击性为核心优势。其分子结构经过特殊优化,配合增韧改性剂,在保持高透明度的同时显著提升抗冲击强度,可承受外力撞击而不易开裂或破碎,适用于对耐用性要求严苛的场景。

应用领域

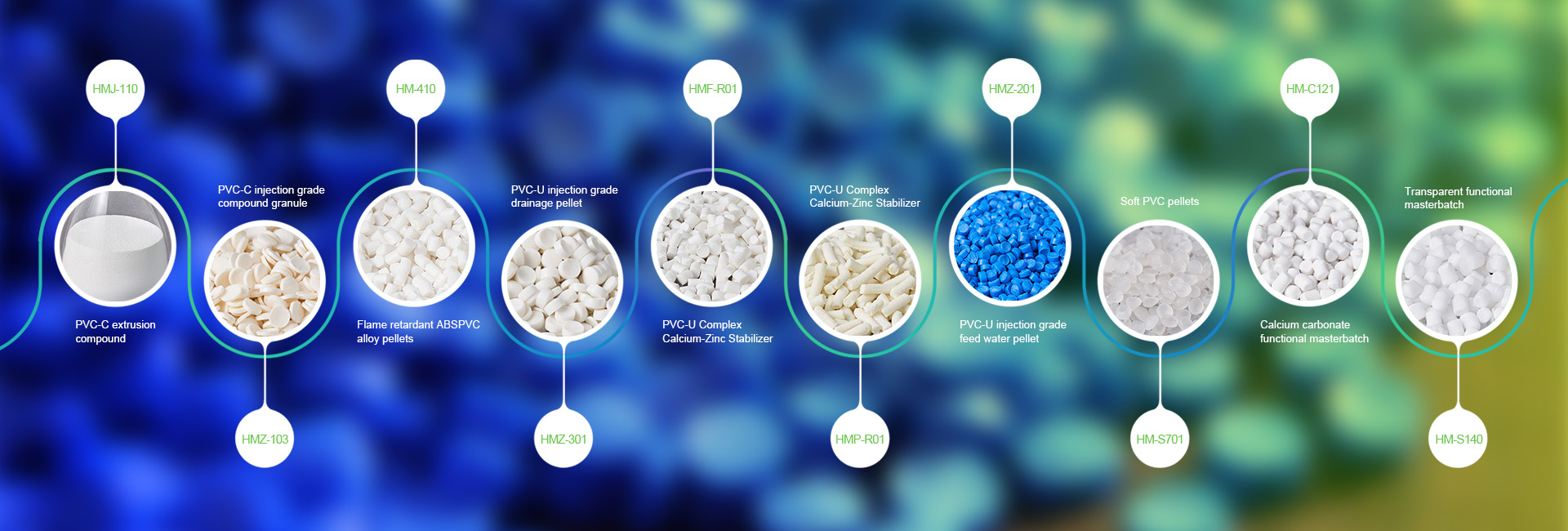

主要产品

-

硬质PVC颗粒

-

软质PVC颗粒

-

ABS合金料

-

CPVC混配料

-

PVC稳定剂

-

填充母粒

为什么选择我们?

追本溯源,高兰德(广东)新材料科技有限公司源于中国广东省广州化工厂。而广州化工厂成立于1956年,是一家从事氯碱工业的国有企业,生产PVC树脂等原材料,是中国PVC塑料行业开拓者之一。

严格的质量保证

保持产品的稳定性和一致性是制造业最求的最高目标,我们通过控制五大要素实现产品质量稳定性和一致性,4M1E法是质量管理的有效工具,指人员(Man)、机器(Machine)、物料(Material)、方法(Method)和环境(Environment)五大要素的有效组合合

人员(Man)

指生产过程中的操作者,需具备专业技能和质量意识。其能力直接影响产品质量稳定性。

机器(Machine)

包括生产设备、检测仪器等,设备状态和维护水平决定生产效率和产品精度。

物料(Material)

原材料质量、规格符合性及存储管理,是产品质量的基础保障。

方法(Method)

涵盖工艺流程、操作标准和检测规范,确保技术措施科学性和可操作性。

环境(Environment)

包含温湿度等自然条件、作业场地布局和管理制度,间接制约生产质量。

60多年的专业经验

我们起源于广州化工厂(成立于1956年),一直专注于PVC行业,从未间断,是中国PVC行业的先驱。

免费提供全过程的顾问服务

PVC的化学和物理结构使它在聚合物世界非常独特,生产出一款出众的PVC制品,需要从产品设计、模具和生产设备、原料的配方、加工工艺有效组合,缺一不可。我们专注服务于中小企业,可以免费为我们的客户提供全过程的顾问服务,实现无缝协作。

新闻动态

2025樟木头塑博会PVC原料参展总结:在创新浪潮中锚定价值坐标

为期三天的2025东莞樟木头塑胶产业国际博览会已圆满落幕。作为扎根华南塑胶产业核心的PVC原料参展商,我们依托展会搭建的全产业链交流平台,在技术展示、供需对接与行业洞察中收获颇丰,更清晰地把握了PVC···

第33届广州博览会丨高兰德(广东)新材料科技有限公司

聚势羊城,链接全球--高兰德(广东)新材料科技有限公司亮相第33届广州博览会圆满收官8月22日至24日,第33届广州博览会于中国进出口商品交易会展馆盛大举行。本届广博会以“创新赋能 共赢共享”为主题,···